Cryogenic liquid containers, also referred to as liquid cylinders, are double-walled vacuum vessels with multilayer insulation in the annular space. They are designed for the reliable and economic transportation and storage of liquefied gases at cryogenic temperatures, typically colder than –130°F (–90°C). There are two primary advantages of a liquid container. The first is that it contains a large volume of gas at a relatively low pressure compared to a compressed gas cylinder. The second is that it provides a source of cryogenic liquids which can be easily handled. Cryogenic liquid containers are often incorrectly referred to as dewars. Dewars are open, nonpressurized vessels for holding cryogenic liquids.

The cryogenic products normally found in liquid containers are liquid nitrogen (LIN), liquid argon (LAR), liquid oxygen (LOX), and liquid helium (LHE). Carbon dioxide and nitrous oxide are also available as refrigerated liquids in similar containers.

Although these containers are well insulated, heat will continuously leak into the product, due to the extremely large temperature difference between the cryogenic liquid and the ambient environment. The heat leak will cause some vaporization to occur. Vaporized product, if not used, will collect in the vapor space above the liquid and build pressure. This is referred to as head pressure. The head pressure will build in the container and periodically vent via the pressure relief valve. Vaporization rates will vary and may be as low as 0.4% or as high as 3% of the container’s volume per day.This is a normal and safe function of the container.

The user of any cryogenic liquid container should be thoroughly familiar with the product and the mechanical workings of the container before using the product.

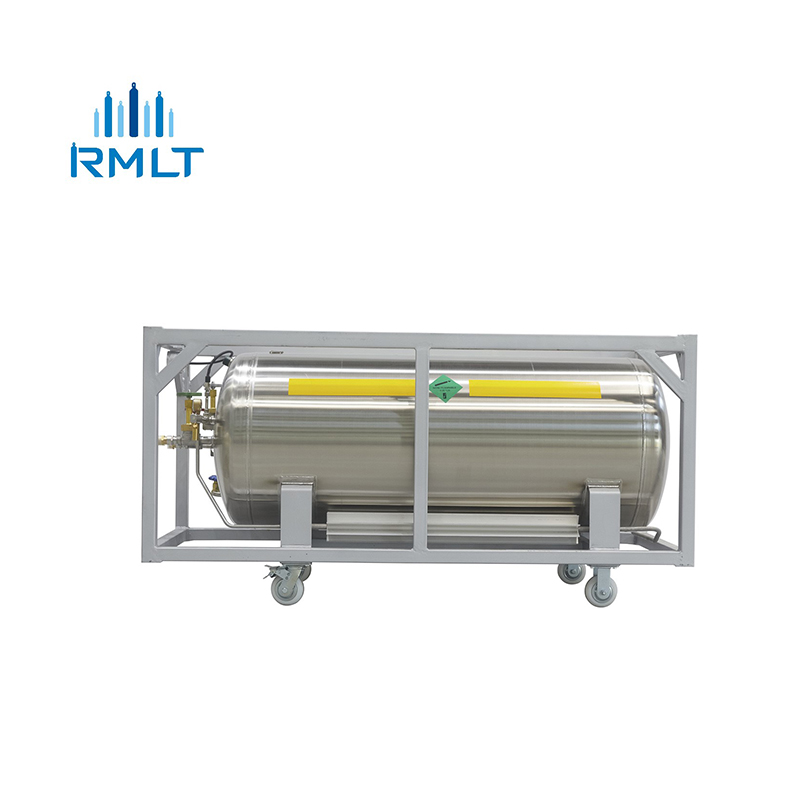

The cryogenic liquid cylinders we produced adopted the advanced techniques and the whole production process is under the strict quality-guarantee control system. It can be applied to store, transport the cryogenic liquefied gas products (liquid oxygen, liquid argon, liquid nitrogen, liquid natural gas, liquid CO2, etc),and it can automatically provide continue gases.

Features:

1. Mainly used in storage and transportation of liquid oxygen, liquid nitrogen, liquid argon, and liquefied natural gas

2. Adopted high multi-layer insulation method to ensure the low evaporation rate.

3. Inner vaporizer provides a 10Nm3/h stable continuous gas.

4. Solar installation use in the priority of gas-pressure and gas space.

5. Adopt the international CGA standard tie-in and all the valves installed imported from USA ( Rego Brand)

6. Unique design of damping ring meets the needs of frequent transportation.

7. Suitable for electronics, research, chemical industry, welding, and LNG supply industries.

Packing detail:

The oxygen cylinder was packed by pallets,wrapped by PVC, or was packed by woven bag, or was packed by poly net, or according to customer's requirements.

Delivery time:

Shipment will be effected within 15 days